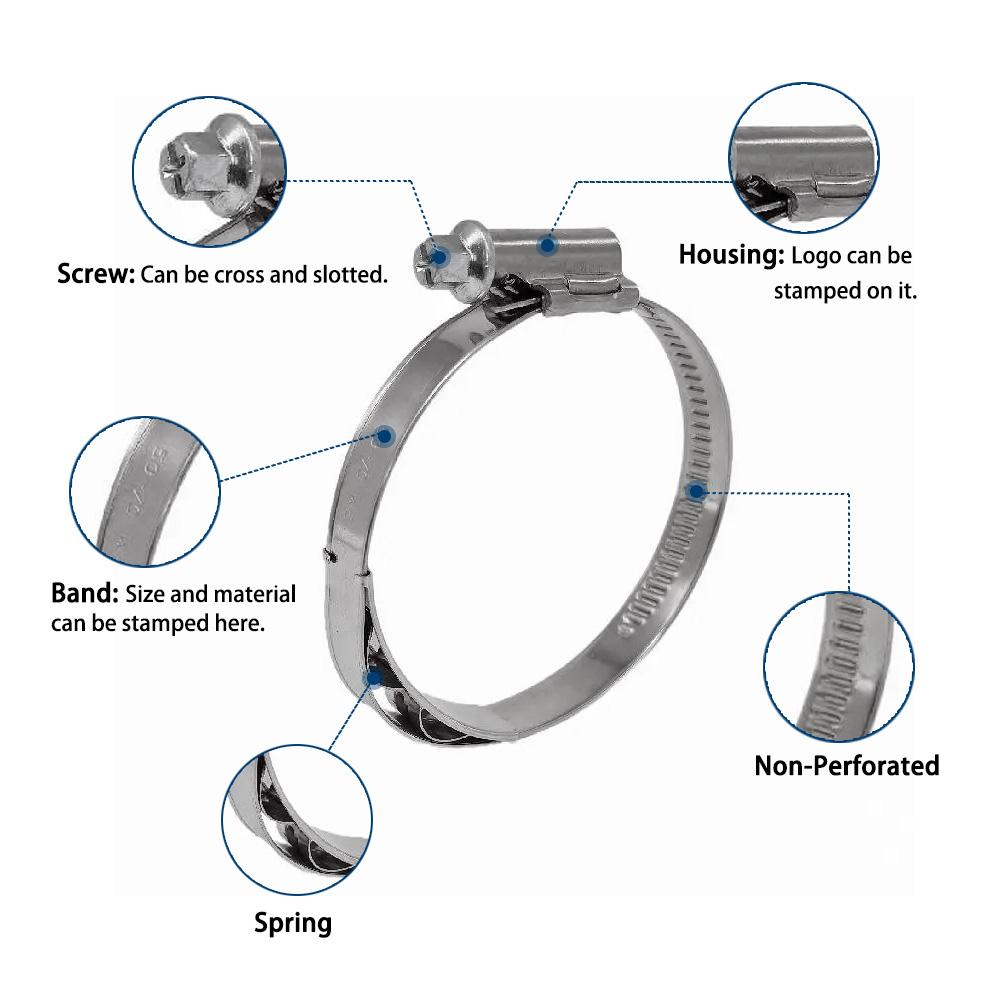

Worm Drive Hose Clamp with Spring: The Ultimate Solution for Secure Hose Connections

Worm Drive Hose Clamp with Spring is the ideal choice for applications requiring a reliable and adjustable hose securing solution. Designed to offer automatic tension adjustment, this worm gear hose clamp combines the benefits of a traditional worm drive hose clamp with the added feature of a spring mechanism, ensuring a secure fit in even the most demanding environments. Whether you’re working in the automotive, agricultural, or industrial sectors, the YOUDE Hose Clamp guarantees a stable and leak-proof connection.

Advantages and Special Applications of Worm Drive Hose Clamp with Spring

The Worm Drive Hose Clamp with Spring offers unique benefits compared to standard Worm Drive Hose Clamps, especially in environments with dynamic pressure, temperature fluctuations, or vibration. Here are the main advantages and uses:

- Automatic Tension Adjustment

The Worm Drive Hose Clamp with Spring automatically adjusts the clamping force as temperature, pressure, or hose size changes. This prevents over-tightening or loosening, ensuring a stable and leak-proof connection in fluctuating environments, such as those with temperature or vibration variations.

- Adaptability to High-Pressure Environments

In high-pressure liquid or gas systems, the Worm Drive Hose Clamp with Spring ensures consistent pressure between the hose and connector, reducing leakage risk. The spring mechanism helps prevent loosening caused by pressure fluctuations, enhancing the clamp’s sealing ability and safety.

- Enhanced Vibration Resistance

In high-vibration environments (like automotive engines or industrial machinery), traditional hose clamps may loosen due to vibrations. The Worm Drive Hose Clamp with Spring maintains stable clamping force, preventing leaks or disconnections by adapting to vibration, thus ensuring secure connections.

- Ideal for Dynamic Applications

This clamp is perfect for applications requiring dynamic adjustment of clamping force, such as systems with fluctuating fluid flow or temperature. The spring ensures consistent pressure and reliable sealing, providing superior performance in dynamic environments.

- Extended Hose Life

The Worm Drive Hose Clamp with Spring adjusts pressure according to hose expansion or contraction, reducing wear and damage caused by over-tightening or excessive loosening. This extends hose life by distributing pressure more evenly compared to traditional hose clamps.

- Improved Sealing Performance

The spring ensures the clamp maintains a secure seal over time, compensating for any dimensional changes in the hose due to environmental shifts, especially in high-temperature and high-pressure applications. This improved sealing is crucial in demanding industrial and automotive systems.

- Suitable for Special Liquid or Gas Transport

For transporting corrosive or toxic substances, the Worm Drive Hose Clamp with Spring adapts to pressure changes within the hose, maintaining a stable seal. The spring mechanism ensures the clamp stays secure, minimizing the risk of leaks in harsh environments.

Contact us to provide you with the wholesale solution of hose clamps suitable for you!