At Youde, quality is the basis of everything we do. As a confidence manufacturer of hoses, we understand that our products play a fundamental role in guaranteeing the safety and reliability of our customers’ applications. That is why we have implemented a rigorous quality control process, backed by advanced equipment and inspection technologies.

Our specialized quality control equipment uses latest generation tools, such as measurement instruments, traction checks, saline fog tests, etc., to meticulously inspect each batch of hoses clamps. From the integrity of the material to dimensional precision and corrosion resistance, we do not leave any details without reviewing.

Test equipment: PMI test machine

Proof offered: to verify the degree of the WIP component material and finished

Acceptance criteria: according to ASTM standard

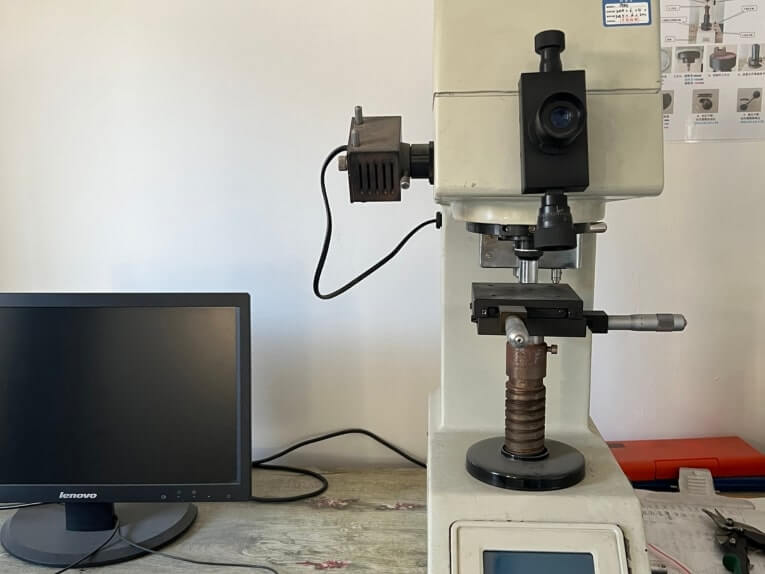

Test Equipment: Vickers Hardness Tester

Test Offered: To Check the surface Hardness of Sheet metal

Specification: 1) Load Range: 0.5-50 Kg. 2) Minimum thickness of material can be tested : 0.5mm. 3) Hardness Range at 5Kg loading :- 31.08 – 1449 VPN.

Test Equipment: Rockwell Hardness Tester

Test Offered: To Check the surface Hardness of metal.

Specification: Loading Range: 100Kg, 150 Kg

Range: 1) 1-100 HRB 2) 1- 100 HRC.

Test Equipment: PMI Testing Machine

Test Offered: To verify the Material Grade of WIP & finished component

Acceptance Criteria: As per ASTM Standard

Test Equipment: Tensile Machine

Test Offered: To confirm yield strength, percentage of elongation and Ultimate Tensile Strength of specimen

Tests performed: Compressive strength, Tensile strength, Shear strength

Test Equipment: Salt-Spray Test Machine

Test Offered: To evaluate the corrosion resistance of materials and surface coatings.

Specification: 1) Standard Followed: ASTM B 117. 2) PH value – 6.7. 3) Flow rate- 30ml in 24 Hrs.